הדרך המדויקת ביותר לענות על שאלה זו היא על ידי ציטוט ההגדרה הסטנדרטית ISO של חדר נקי. זהו הסטנדרט שכל החדרים הנקיים חייבים לעמוד בו וההסבר הבא נותן את הפרמטרים המגדירים של חדר נקי.

חדר נקי הוא "חדר שבתוכו נשלט ומסווג ריכוז המספרים של החלקיקים הנישאים באוויר, ואשר מתוכנן, נבנה ומופעל באופן שישלוט על החדרתם, יצירתם ושימורם של חלקיקים בתוך החדר".

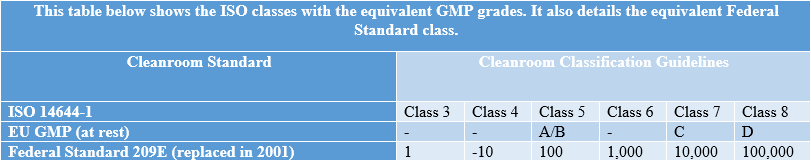

Cleanroom Classification Tables

Discover the different classes within the cleanroom ISO standards and their Federal Standard and GMP equivalent. These tables detail the particle counts that define each class.

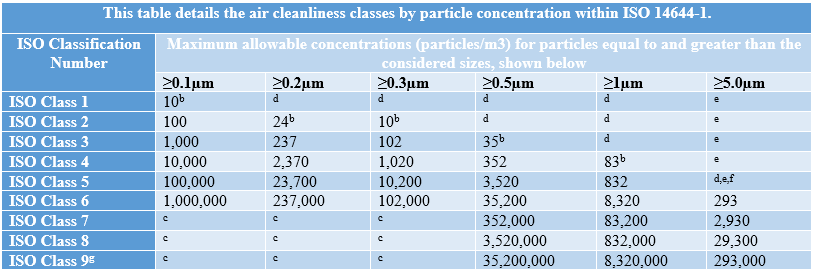

ISO 14644-1:2015 Cleanroom Classification

ISO 14644 is the international standard for cleanrooms and associated controlled environments. Part 1 details the classification of air cleanliness by particle concentration.

a All concentrations in the table are cumulative, e.g. for ISO Class 5, the 10,200 particles shown at 0.3µm include all particles equal to and greater than this size.

b These concentrations will lead to air sample volumes for classification. Sequential sampling procedure may be applied.

c Concentration limits are not applicable in this region of the table due to very high particle concentration.

d Sampling and statistical limitations for particles in low concentrations make classification inappropriate.

e Sample collection limitations for both particles in low concentrations and sizes greater than 1µm make classification at this particle size inappropriate, due to potential losses in the sampling system.

f In order to specify at this particle size in association with ISO Class 5, the macroparticle descriptor M may be adapted and used in conjunction with at least one other particle size.

g This class is only applicable for the in-operation state.

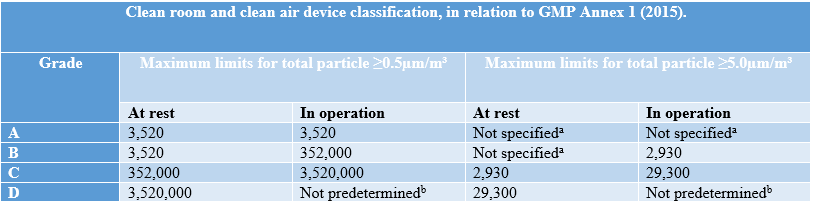

Maximum permitted total particle concentration for classification by GMP grade

GMP Annex 1 details the maximum permitted particle concentrations for classification, for 'at rest' and 'in operation' states.

a Classification including 5µm particles may be considered where indicated by the CCS or historical trends.

b For grade D, in operation limits are not predetermined. The manufacturer should establish in operation limits based on a risk assessment and routine data where applicable.

Comparison of Cleanroom Classifications

The 'at rest' limits for GMP, correspond with the limits for ISO classes.